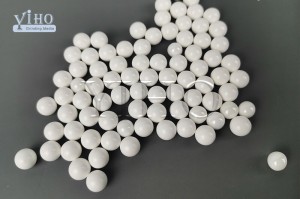

I-Alumina (Al2O3) Iibhola zokuSila

Iibhola zokusila ze-alumina zisetyenziswa ngokubanzi kwii-mill zebhola njengemithombo yeendaba ezirhabaxa kwizinto ze-ceramic ekrwada kunye nemathiriyeli ye-glaze.Iifektri zeCeramic, zesamente kunye ne-enamel kunye nezityalo ezisebenza ngeglasi ziyazisebenzisa ngenxa yokugqwesa koxinzelelo oluphezulu, ukuqina kwazo okuphezulu, kunye nokunganyangeki kwazo okuphezulu.Ngethuba lokucutshungulwa kwe-abrasive / ukugaya, iibhola ze-ceramic aziyi kunqabile ukuphulwa kwaye i-contamination factor incinci.

Iingenelo

I-1.I-high wear-resistanceIibhola ezigayiweyo zokugqoka ziphezulu kuneebhola ze-alumina eziqhelekileyo, xa zisebenza, ibhola ayiyi kungcolisa izinto zokugaya, ngoko inokugcina ubunyulu kunye nokuphucula ukuzinza kwezinto ezigayiweyo ngokukodwa i-ceramic glaze.

2.Uxinaniso oluphezuluUbuninzi obuphezulu, ubulukhuni obuphezulu kunye neempawu zokusila eziphezulu zigcina ixesha lokusila, ukwandisa igumbi lokutyumza.Ngoko inokuphucula ukusebenza kakuhle kokusila.

Iimpawu eziphambili ze-Alumina (Al2O3) Iibhola zokuSila Uhlobo lwe-92

| Into | Ixabiso |

| AL2O3 | >92% |

| SiO2 | 3.8 % |

| Fe2O3 | 0.06 % |

| TiO2 | 0.02 % |

| Okunye | 2.5 % |

| Ukufunxwa kwamanzi | <0.01 % |

| Ubuninzi obuqinileyo | >3.6 g/cm3 |

| Ubuninzi beVolumetric bulk | 1.5-1.8 kg / l |

| Mohs ubunzima (iBanga) | 9 |

| Ilahleko yokuncama | <0.015 % |

| Umbala | mhlophe |

Ubungakanani

| Ububanzi (mm) | Φ 0.5-1 | Φ 2 | Φ 3 | Φ 5 | Φ8 | Φ 10 | Φ13 | Φ15-60 |

| Ukunyamezela (mm) | / | ±0.3 | ±0.3 | ±0.3 | ±0.3 | ±0.3 | ±0.3 | Φ±0.5-2mm |

Okunye

Sikwanazo zonke iisayizi zeebhola ze-Al2O3 phakathi kwe-Φ3mm kunye ne-Φ60mm.Eminye imixholo ye-Al2O3 60%,75%, 92%, 99%.