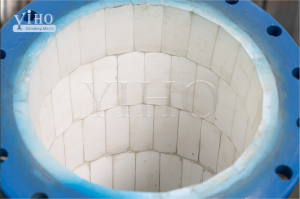

Ceramic Lined Wye Feed Umbhobho & Tees

I-pipe wyes kunye neetiyi zeepayipi

Ii-pipe wyes zifana nee tee zepayipi.Umahluko kuphela kukuba umgca wesebe une-engile ukunciphisa ukukhuhlana okunokuphazamisa ukuhamba.Ukudibanisa kombhobho ngokuqhelekileyo kwi-angle ye-45-degree kune-angle eqhelekileyo ye-90-degree.Ukuba isebe liya kuthi ekugqibeleni libe li-perpendicular ukuya kumgca wokudlula, ukufakwa kombhobho kuba yi "tee wye".

Iipropati eziphambili zeCeramic

| Udidi | HC92 | HC95 | HCT95 |

| Al2O3 | ≥92% | ≥95% | ≥95% |

| ZrO2 | / | / | / |

| Ukuxinana | ≥3.60g/cm3 | ≥3.65g/cm3 | ≥3.70g/cm3 |

| Ukufunxwa kwamanzi | ≤0.1% | ≤0.1% | ≤0.1% |

| HV 20 | ≥950 | ≥1000 | ≥1100 |

| Ukuqina Kwamatye HRA | ≥82 | ≥85 | ≥88 |

| Ukugoba Amandla eMPa | ≥220 | ≥250 | ≥300 |

| Amandla oxinzelelo lweMPa | ≥1050 | ≥1300 | ≥1600 |

| Ukuqhekeka kokuqina kwe-KIc MPam 1/2 | ≥3.7 | ≥3.8 | ≥4.0 |

| Nxiba iVolume | ≤0.25cm3 | ≤0.20cm3 | ≤0.15cm3 |

Iimpawu ze-ceramic composite pipe

Ukumelana nokunxiba kakuhle

Umbhobho we-Ceramic composite ngenxa ye-corundum ceramic (a-AL2O3), ubulukhuni be-Mohs be-9.0 bulingana nokungaphezulu kwe-HRC90.Ke ngoko, inokumelana nokunxiba okuphezulu kumajelo eendaba abrasive ahanjiswa ngamashishini afana nesinyithi, amandla ombane, imigodi, kunye namalahle.Kuye kwaqinisekiswa ngokusebenza kwemizi-mveliso ukuba ubomi bayo bokugqoka buphindwe kashumi okanye namaxesha amaninzi alishumi kunentsimbi eqinile.

Ukuchasana kokusebenza okuncinci

Umbhobho we-SHS ceramic composite ayifani nomgca weconvex spiral kumphezulu ongaphakathi wombhobho wentsimbi ongenamthungo kuba umphezulu ongaphakathi ugudile kwaye awukhe udle dleke.Uburhabaxa bangaphakathi kunye neempawu ezicacileyo zokunganyangeki kwamanzi kwiiyunithi zovavanyo ezifanelekileyo zavavanywa.Ukuguda kwendawo yangaphakathi kwakungcono kunomnye umbhobho wesinyithi.I-coefficient yokutsala ecacileyo yayiyi-0.0193, eyayingaphantsi kancinci kunombhobho ongenamthungo.Ngoko ke, ityhubhu ineempawu zokumelana nokuqhuba okuncinci kwaye inokunciphisa iindleko zokusebenza.

Umhlwa, anti-scaling

Ekubeni i-steel ceramic layer (a-AL2O3), yinto engathathi hlangothi.Ngoko ke, iyamelana ne-asidi kunye ne-alkali kunye ne-corrosion yamanzi olwandle, kwaye ikwanazo iimpawu zokuchasa ukulinganisa.

Ukumelana nobushushu kunye nokumelana nobushushu

Ngenxa ye-ceramic ye-corundum (a-AL2O3), sisakhiwo esisodwa esizinzile se-crystalline.Ngoko ke, umbhobho odibeneyo unokusebenza ngokuqhelekileyo kwiqondo lokushisa elide -50--700 ° C.I-coefficient yokwandiswa komgca wezinto eziphathekayo we-6-8 × 10-6 / 0C, malunga ne-1/2 yepayipi yensimbi.Izinto eziphathekayo zinokuzinza kakuhle kwe-thermal.

Iindleko zeprojekthi ziphantsi

Imibhobho edibeneyo yeCeramic inobunzima obulula kwaye iyafikeleleka.I-50% ikhaphukhaphu kunetyhubhu yamatye etyhidiweyo enobubanzi obungaphakathi obufanayo;i-20-30% ilula kunetyhubhu ye-alloy engagugiyo, kwaye inokumelana nokunxiba kakuhle kunye nokumelana nokugqwala ngenxa yobomi bayo obude benkonzo, ngaloo ndlela ixhasa iindleko ze-hanger, iindleko zokuthutha, iifizi zokufakela, kunye nokunciphisa iindleko zokusebenza.Ukuthelekisa uhlahlo lwabiwo-mali lweprojekthi yeziko loyilo kunye neyunithi yokwakha kunye neprojekthi yangempela, iindleko zeprojekthi zilingana nelitye elityhidiweyo.Xa kuthelekiswa nombhobho we-alloy-resistant-resistant alloy, iindleko zeprojekthi ziyancipha malunga ne-20%.

Ufakelo olulula nolwakhiwo

Ngenxa yobunzima bayo obulula kunye nokusebenza kakuhle kwe-welding.Ngoko ke, i-welding, i-flanges, ukudibanisa ngokukhawuleza, njl.

Isicelo

Iingqiniba zemibhobho ene-Ceramic zinokusetyenziswa kwiindawo zempompo yekhonkrithi ngenxa yeenzuzo zazo, ngakumbi ubunzima obuphantsi, obunceda ukunqanda i-jam ngexesha lokuthutha ikhonkrithi.

Buyisela umbhobho we-carbon steel, umbhobho wensimbi engenasici kunye ne-SDR

Ukukhutshwa kwezinto eziphathekayo eziphezulu

Ukutya kweMagnetite kunye nemigca yokukhupha amanzi

Umsila ungaphantsi