Ufakelo lwemibhobho efakwe kwimikhono yeCeramic efakwe kwishishini lemigodi

Malunga nemikhono yeCeramic enemikhono yombhobho yofakelo

Umkhono omkhulu wedayamitha yeseramic usoloko uyingxaki enkulu kubavelisi betyhubhu yeceramic kuba kunzima kakhulu ukulawula izinga loguquko lomkhono wekeramic emva kokuba sintering. ayizukubonisa kuphela amandla emveliso yenkampani, kodwa itekhnoloji yenkampani.Okwangoku, umzi-mveliso wethu unazo zombini izibonelelo zokunxiba izixhobo zokucinezela ze-ceramic ezixhathisayo kunye netekhnoloji.

Siye sadibana nobunzima xa sisenza imikhono yeceramic kwaye sajongana nazo zonke iingxaki emva kwemigudu yophando lwethu kunye nabantu bobunjineli .Kwakhona senze umatshini wofakelo olula kakhulu ukwenza ufakelo lomkhono weceramic kwimibhobho kuba umkhono unzima kakhulu. enkulu kwaye inzima .Emva kwenyanga sisebenza , sagqiba le 20 'isikhongozeli 95% i-alumina sleeve sleeve enemikhono efakwe imibhobho ,imibhobho ye-T kunye neengqiniba kunye nabathengi baxatyiswa kakhulu malunga nokusabela kwethu ngokukhawuleza kunye neenzame ezinkulu kule projekthi ezisetyenziswa kwinkqubo yokuhambisa imigodi. .

I-Sintering njengetyhubhu ye-ceramic epheleleyo okanye umkhono we-ceramic, kwaye emva koko uyidibanise kumbhobho wentsimbi okanye umbhobho wentsimbi engatyiwayo kunye ne-epoxy encamathelayo yokumelana nobushushu obuphezulu.Umbhobho we-ceramic onemikhono efakwe kwi-ceramic usebenzise kakhulu kwishishini lemigodi, njengombhobho wemigodi eludaka, umbhobho wokususa uthuli lwemigodi, umbhobho ohambisa i-slag, ingqiniba kunye nemibhobho ye-T.

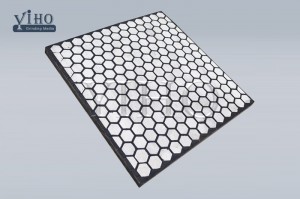

Olu hlobo lombhobho we-ceramic owenziwe nge-ceramic uquka iinxalenye ezintathu (umbhobho wensimbi + i-adhesive + tiles ze-ceramic), umbhobho wensimbi wenziwa ngombhobho we-carbon steel ongenamthungo.Iitayile ze-ceramic ziyi-95% ye-alumina ephezulu, kwaye i-bonding yi-adhesive epoxy ephezulu yokushisa ukuya kwi-350oC. Olu hlobo lombhobho lufanelekile ukuthuthwa kwepowder ngaphandle kokuwa kwe-tile okanye ukuguga ukusebenza phantsi kwe-350oC ixesha elide.Ubomi benkonzo buhlala ngamaxesha angama-4 ukuya kuma-5 kunombhobho wensimbi oqhelekileyo.

Ufakelo lwemibhobho enemikhono yeCeramic Umda wosetyenziso

Le Mibhobho esetyenziselwa i-Pneumatic kunye ne-Hydraulic Systems ihlupheka ngenxa yokugqoka okuphezulu, ukutyibilika okuphezulu kunye nefuthe eliphezulu, ngakumbi kwii-elbows.Singakwazi kwakhona ukuyila izifakelo zemibhobho yesiko ukuhlangabezana nezicelo ezahlukeneyo zokusebenza.

Izixhobo zeTile zokunxiba iiCeramic kunye neefoto

-92% iAlumina

-95% iAlumina

-99% iAlumina

-RBSiC Silicon carbide

-Umgca we-ZTA

| Udidi | HC92 | HC95 | HCT95 | HC99 | I-HC-ZTA |

| Al2O3 | ≥92% | ≥95% | ≥ 95% | ≥ 99% | ≥75% |

| ZrO2 | / | / | / | / | ≥21% |

| Ukuxinana (g/cm3 ) | >3.60 | >3.65g | >3.70 | >3.83 | >4.10 |

| HV 20 | ≥950 | ≥1000 | ≥1100 | ≥1200 | ≥1350 |

| Ukuqina Kwamatye HRA | ≥82 | ≥85 | ≥88 | ≥90 | ≥90 |

| Ukugoba Amandla eMPa | ≥220 | ≥250 | ≥300 | ≥330 | ≥400 |

| Amandla oxinzelelo lweMPa | ≥1050 | ≥1300 | ≥1600 | ≥1800 | ≥2000 |

| Ukuqina Kokwaphuka (Kic MPam 1/2) | ≥3.7 | ≥3.8 | ≥4.0 | ≥4.2 | ≥4.5 |

| Nxiba umthamo (cm3) | ≤0.25 | ≤0.20 | ≤0.15 | ≤0.10 | ≤0.05 |