Ukumbiwa kwamalahle ngeCeramic eGqotyiweyo yePlate yeLining eWeldable

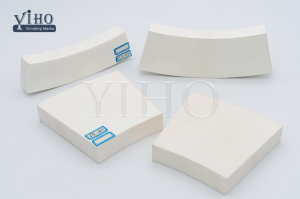

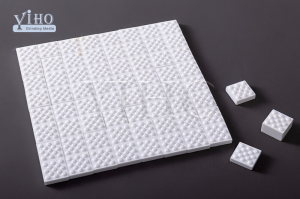

I-Ceramic Perforated Lining Plate Intshayelelo yeThayile eWeldable

I-YIHO inikezela kwaye ifake uluhlu olubanzi lwe-Alumina Wear Resistant Tiles ukukhusela ukunxiba kuzo zonke iindawo ezifana ne-Chutes, Silos, Feeders, Bins, Launders, Dutching, Tanks, Bunkers, Hoppers, Underpans njl.

Ichazwa njengezinto zexesha elizayo, i-alumina ceramics yenye yezona zinto zinzima kuzo zonke izinto zendalo ezaziwa ngumntu.Phantsi kweemeko ezirhabaxa kakhulu, akukho mathiriyeli unokukhuphisana ngeendleko zobomi kunye nobunzima obugqithisileyo kunye nokumelana nokunxiba.Ukongeza, i-alumina ceramics ineekhemikhali ezikhethekileyo, oomatshini, i-thermal kunye nepropathi yokugquma umbane kwaye inokwakheka kuyo nayiphi na imilo okanye ubungakanani obuneempawu ezahlukeneyo zezicelo ezithile.

Iithayile ze-Weld-On alumina ceramic zidla ngokusetyenziswa kwizicelo zobushushu obuphezulu kwaye ziyafumaneka kuninzi lweesayizi ukuze zilungele isicelo sakho kwisiseko sangaphambili sesitokhwe.

ICeramic Perforated Lining Plate Weldable Tile yedatha yobuGcisa

| Udidi | HC92 | HC95 | HCT95 | HC99 | I-HC-ZTA | ZrO2 |

| Al2O3 | ≥92% | ≥95% | ≥ 95% | ≥ 99% | ≥75% | / |

| ZrO2 | / | / | / | / | ≥21% | ≥95% |

| Ukuxinana (g/cm3 ) | >3.60 | >3.65g | >3.70 | >3.83 | >4.10 | >5.90 |

| HV 20 | ≥950 | ≥1000 | ≥1100 | ≥1200 | ≥1350 | ≥1100 |

| Ukuqina Kwamatye HRA | ≥82 | ≥85 | ≥88 | ≥90 | ≥90 | ≥88 |

| Ukugoba Amandla eMPa | ≥220 | ≥250 | ≥300 | ≥330 | ≥400 | ≥800 |

| Amandla oxinzelelo lweMPa | ≥1050 | ≥1300 | ≥1600 | ≥1800 | ≥2000 | / |

| Ukuqina Kokwaphuka (Kic MPam 1/2) | ≥3.7 | ≥3.8 | ≥4.0 | ≥4.2 | ≥4.5 | ≥7.0 |

| Nxiba umthamo (cm3) | ≤0.25 | ≤0.20 | ≤0.15 | ≤0.10 | ≤0.05 | ≤0.02 |

I-Ceramic Perforated Lining Plate I-Weldable Tile ye-Tile Advantages

Iithayile ze-alumina ezinokuweldable, ezikwabizwa ngokuba yi-alumina ceramic weld-on tiles okanye ii-ceramic weldable linings, zibonelela ngeenzuzo ezininzi xa zisetyenziswa kwizicelo zokunganxibi.Ezi tiles ziqhele ukusetyenziswa ukukhusela izixhobo zemizi-mveliso kunye nomphezulu ukusuka kwi-abrasion, impembelelo, kunye nokunxiba.Nazi ezinye zezibonelelo eziphambili zeethayile ze-alumina ezinokudityaniswa:

1. Ubunzima obuphezulu kunye nokuNxilwa koMgqomo: I-aluminium ye-ceramic yenye yezona zinto zinzima kakhulu, zibonelela ngokugqwesileyo kokugqoka kunye nokuqina.Iithayile ezidityanisiweyo ezenziwe nge-alumina zilungele ukukhusela izixhobo kunye nemigangatho evezwe kwizinto ezirhabaxa.

2. Ukuchasana kweMichiza kunye nokuRhwalala: I-Alumina i-inert yekhemikhali kwaye ixhathisa kakhulu kwizinto ezitshabalalisayo, iyenza ifaneleke ukusetyenziswa kumashishini aneemeko zeekhemikhali ezinobundlobongela.

3. Ukumelana nokushisa: Iithayile ze-alumina ezidibeneyo ziyakwazi ukumelana nokushisa okuphezulu ngaphandle kokuthotywa okuphawulekayo kwiipropati zabo, okwenza ukuba zilungele izicelo ezibandakanya ukushisa okuphezulu okanye ukutshitshiswa kwe-thermal.

4. I-Uniform Surface: Iithayile zibonelela ngomphezulu ogudileyo kunye nofanayo, ukunciphisa ukwakhiwa kwezinto kunye nokuqinisekisa ukuhamba kwezinto eziphathekayo, okubalulekileyo kwiinkqubo ezithile zemizi-mveliso.

5. Ukulula ukuFakela: Njengoko igama libonisa, iileyile ze-weldable zenzelwe ukufakwa lula usebenzisa ubuchule be-welding.Oku kuvumela ukuncamathisela ngokukhawuleza kunye nokukhuselekileyo kwi-substrate, ukunciphisa ixesha lokuphumla ngexesha lofakelo kunye nokugcinwa.

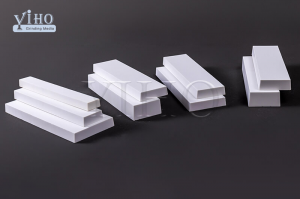

6. IiMilo kunye nobukhulu obuLungisayo: Iithayile ze-alumina ezidibeneyo zinokwenziwa ngeendlela ezahlukeneyo kunye nobukhulu ukuze zilungele izixhobo ezithile okanye iindawo, zibonelela ngokuguquguqukayo kuyilo kunye nokuqinisekisa ukugubungela okupheleleyo kweendawo zokugqoka.

7. Ukunciphisa ixesha loLondolozo lokuNcitshiswa: Ngokukhusela izixhobo ezingaphantsi kokutshatyalaliswa kunye nokulimala, iileyile ze-alumina ezidibanisayo zandisa ubomi bokusebenza kwezixhobo, ukunciphisa ukuphindaphinda kokugcinwa kunye nokunciphisa ixesha.

8. Iindleko eziSebenzayo: Nangona iileyile ze-alumina ezidibanisayo zinokuba neendleko eziphezulu zokuqala xa kuthelekiswa nezinye izinto, ubomi babo obude kunye nokunciphisa iimfuno zokulondoloza zenza ukuba zibe neendleko eziphezulu kwixesha elide.

9. Ukugqunywa koMbane: I-Alumina iyisithinteli sombane esigqwesileyo, esenza ukuba ifaneleke kwizicelo apho ukuhanjiswa kombane kufuneka kugwenywe.

10. Ukuhambelana neeSubstrates ezahlukeneyo: Iithayile ze-aluminium weldable zingasetyenziswa kwii-substrates ezahlukeneyo, kubandakanywa intsimbi, ikhonkrithi, kunye nezinye izinto, ezenza ukuba zisebenziseke kwiintlobo ezininzi zezicelo zoshishino.

Ngokubanzi, iithayile ze-alumina ezidibanisayo zibonelela ngesisombululo esithembekileyo nesisebenzayo kwizicelo ezinganyangekiyo, zibonelela ngokhuseleko ngokuchasene ne-abrasion, impembelelo kunye nokuhlaselwa kweekhemikhali.Ukuqina kwabo, ukukhululeka kofakelo, kunye nexesha elide-ukuphumelela kweendleko kubenza kube yinto ethandwayo kumashishini afana nemigodi, i-samente, isinyithi, ukuveliswa kwamandla, kunye nokuphathwa kwezinto eziphathekayo, apho ukuguga kunye nokukrazula kuyimingeni eqhelekileyo.