Ipleyiti yoKunxitywa kweAlumina eyomileyo

Malunga ne-YIHO Alumina Wear Plate

Yandisa ubomi kunye nokusebenza kweeasethi zakho zokusebenza.

I-Plates ye-Wear iyilwe kwaye iveliselwe ukusetyenziswa kwayo okujoliswe kuyo, ukuqinisekisa ukuba ipleyiti echanekileyo ihlala inconywa kwaye ifakwe.

Ukongeza kwintengiso yeepleyiti zokunxiba, i-HICTECH ibonelela ngezakhono zokufakela ezinikezela ukwaneliseka kwabathengi kunye nexabiso elikhethekileyo.Ngokuququzelelwa licandelo lethu lenkonzo enamava kunye nethembekileyo, siya kuthatha ulawulo lweprojekthi yakho yonke, ukusuka kwinqanaba lokukhawulwa kunye novavanyo, ukuya kukwenziwa, ukuhanjiswa, ukufakela, ukugcinwa kunye nokuqhubekayo emva kwenkonzo yokuthengisa / inkxaso.

Iipleyiti ezinxitywayo zenziwe ngobunjineli ukuze zihambelane nesicelo ngasinye kwaye zineendlela ezahlukeneyo zokulungisa, iipleyiti zokuxhasa intsimbi, i-weld kwiinketho kunye ne-substrate bonding ngokuthe ngqo.

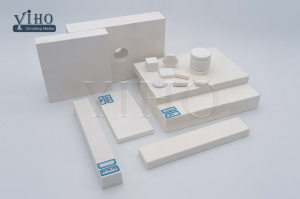

I-Alumina Ceramic Wear Plates

I-Wear Plates yenziwe ngemigangatho ephezulu yomgangatho kunye neenkcukacha, izenza ziphakame kakhulu kunayo nayiphi na enye imveliso kwimarike.

Iimbonakalo

• Iimpawu zokunxiba eziphezulu

• Ithomalalisa impembelelo

• Ukunciphisa ingxolo

• Ucutha ixesha lokuphumla

• Ixabiso eliphantsi ngetoni nganye ye-ROI

• Ilungele injongo

IAlumina yokunxiba iPlate yezicelo

• IiChutes

• IiHoppers

• Amanqaku okutshintshela

• Ukutyumza kunye nokuhlolwa

• Ukugaya

• Uloliwe kunye nezilayishi ngenqanawa

Inkcazo yePlate yeAlumina yokunxiba

| Ukuqamba | Ukutyeba | Ukuxinana |

| Zirconia Toughened Alumina | 12mm, 25mm, 50mm | 4.2gr/cm3 |

| Ialumina 92% / 95% Al203 | 3-75mm | 3.65&3.72gr/cm3 |

| I-Alumina 92% Al203 / Irabha yeNdalo | 8mm-63mm | / |

| IAlumina 92% Al203 / High Tensile Polymer | 10mm-63mm | / |

| Polyurethane | 3mm-20mm | / |

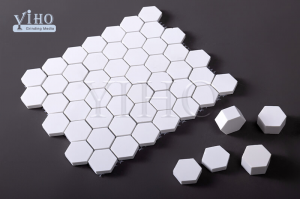

Ukufakwa kwengubo ye-ceramic liner

1. Uncamathiselo oluncamathelayo ngokuthe ngqo: sebenzisa ubushushu begumbi okanye ubushushu obuphezulu obunamandla obuncamathelayo obungabotshwanga ukufaka intlama yokufaka.Kulula ukuyifaka kwaye ilungele impembelelo encinci kunye nobushushu bokusebenza obungaphantsi kwe-350 ℃.

2. I-Stud welding: ingasetyenziselwa izinto zokushisa eziphezulu kunye nezixhobo ezinamandla amakhulu.I-mechanical self-locking force kunye ne-inorganic adhesive inokuqinisekisa ukuba i-liner ayiwi.

3. Ufakelo lwe-ceramic eyenziwe ngaphambili: i-ceramic kufuneka ifakwe kwi-plate yensimbi kuqala ukwenza i-2-in-1 i-ceramic liner (i-ceramic + plate plate), okanye i-3-in-1 i-ceramic liner (i-ceramic + irabha + ipleyiti yensimbi) , kwaye emva koko nge-welding okanye i-countersunk bolts ukuyifaka kwisixhobo, ekulula ukuyilungisa kunye nokutshintsha.

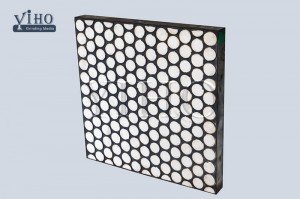

Ucoceko oluPhezulu lweAlumina olunempembelelo oluxhathisa ukunxitywa kwePlate yeLining ye-ceramic exhathisayo

inokutshintsha intsimbi yentsimbi yemanganese, enokusombulula ingxaki yokunxiba.Ubushushu obuphezulu obunganyangekiyo kwilayini yokunxiba budityaniswe kwisixhobo nge-stud welding ye-ZTA engqindilili engqindilili kakhulu, ukuze yenze umaleko oqinileyo wokuchasana nokunxiba.Amanye amaqhuqhuva angqukuva anokuyilwa kwi-lining ukomeleza ngakumbi ukuxhathisa kwayo.Ukuze kube lula ukufakela kunye nokutshintshwa, i-ceramic liner inokufakwa kwi-plate yensimbi kwaye emva koko ifakwe kwisixhobo nge-welding okanye i-countersunk bolts.