Ubunjineli bokunxiba iMatrix yeCeramic

Malunga Nxiba iMatrix yeCeramic

I-Abrasion isoloko ingenakuphepheka ekuqhutyweni nasekuthuthweni kwezinto ezininzi.Ukuhamba kwezinto eziwayo kubangela impembelelo enamandla ngakumbi.Sinika abathengi bethu izisombululo ezingcono nge-matrix yomgangatho ophezulu wokunxiba i-ceramic (kunye / ngaphandle kwepleyiti yentsimbi kunye nebholithi), ukuze sifezekise isiphumo esisiso ekwandiseni ukuchasana kwempembelelo kunye nokunciphisa i-abrasion kunye nengxolo.

Ii-Ceramic Conveyor Wear Liners ziya kunciphisa kakhulu iindleko zakho zokusebenza xa zithelekiswa nayo nayiphi na enye imathiriyeli yelinen.

I-Yiho yenza iintlobo ngeentlobo zeelayini zokunxiba zokuhambisa kwiinketho kunye nobukhulu onokukhetha kuzo.Yenzelwe ukuphatha nasiphi na isicelo esinzima semigodi yelitye.I-Abrasion resistant, i-modular, i-high-wear material ukuya kwii-chutes zebhanti, kunye neendawo zempembelelo zemigqomo.

Nxiba iimpawu zeCeramic Matrix

* Ukumelana nempembelelo ephezulu kakhulu

* Ii-coefficients zokukhuhlana okuphantsi

*Ukunciphisa ingxolo

* Ilula kwaye ikhawuleza i-montage

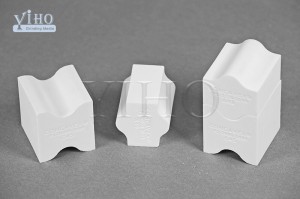

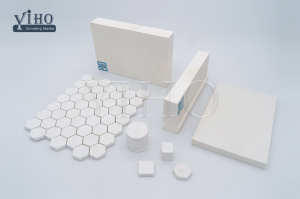

Uhlobo lweeCeramics

Isilinda| Ithayile yeHex | Uxande |Isikwere | Ityhubhu

92%, 95%, 99% Al2O3, ZTA, RBSIC Silicon Carbide

Idatha yobuGcisa:

| Udidi | HC92 | HC95 | HCT95 | HC99 | I-HC-ZTA |

| Al2O3 | ≥92% | ≥95% | ≥ 95% | ≥ 99% | ≥75% |

| ZrO2 | / | / | / | / | ≥21% |

| Ukuxinana (g/cm3 ) | >3.60 | >3.65g | >3.70 | >3.83 | >4.10 |

| HV 20 | ≥950 | ≥1000 | ≥1100 | ≥1200 | ≥1350 |

| Ukuqina Kwamatye HRA | ≥82 | ≥85 | ≥88 | ≥90 | ≥90 |

| Ukugoba Amandla eMPa | ≥220 | ≥250 | ≥300 | ≥330 | ≥400 |

| Amandla oxinzelelo lweMPa | ≥1050 | ≥1300 | ≥1600 | ≥1800 | ≥2000 |

| Ukuqina Kokwaphuka (Kic MPam 1/2) | ≥3.7 | ≥3.8 | ≥4.0 | ≥4.2 | ≥4.5 |

| Nxiba umthamo (cm3) | ≤0.25 | ≤0.20 | ≤0.15 | ≤0.10 | ≤0.05 |

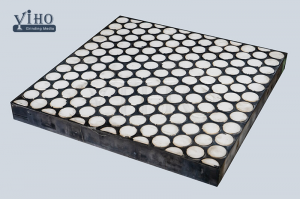

Uhlobo lwe-Wear Matrix

* Irabha exhaswa yi-ceramic matrix

* I-matrix yerabha yerabha exhaswa yintsimbi

Ubungakanani beCeramic Wear Matrix

Rhoqo&Kwenziwe ngokwezifiso,

Ubukhulu be-L800*W800mm

Amashishini abandakanya i-Ceramic Wear Matrix

• I-aggregate

• I-asphalt

• Isamente

• Ikhemikhali

• Ukutshiswa kwamalahle

• Amandla

• Amalahle

• Ukusetyenzwa

• Ukuhlamba

• Isichumisi

• I-Fiberglass

• Bhabha uthuthu

• Ukutya

• Ukusetyenzwa

• Isiseko

• Isanti yeFrac

• Iglasi kunye neFrit

• Iinkozo

• IGypsum

• Intsimbi kunye nentsimbi

• Izimbiwa

• Ukusetyenzwa

• Ukwembiwa kwemigodi

• Iisanti ze-oyile

• I-Oyile neGesi

• I-Petrochemical

• Ipotash

• Intlama kunye nePhepha

• Ikwari

• Ukurisayikilishwa

• Uphahla

• Iimathiriyeli

• Isanti kunye neGrabile

• Iswekile

• Amanzi amdaka

• Umgubo/iMathiriyeli eSininzi

• Ukuphatha

• Iimarike zikhonzwa

• Iyafumaneka

Usetyenziso lweCeramic Wear Matrix

• Imigca eluthuli oluludaka

• IiLiner Mine zeBhola

• Izikrufu zokutyisa amaxolo

• Ukuphatha Amaxolo Amaxolo

• Ibhokisi Ngasemva Engqinibeni

• IiHopper zeClinker

• Izikhongozelo zamalahle

• Iinguqulelo zoMhambisi

• Izitshingitshane

• IiLiner eziYilwayo

• IiLiner zokuqokelelwa kothuli

• Ukukhupha iFan

• Izindlu

• Imibhobho yokuphuma

• Ukutya iiChutes

• Iingqiniba eziMcaba

• Imizila yeGas Scrubber

• Ukuphathwa kwamafutha eehagu

• Izindlu zeefeni zesazisi

• Izindlu zeMill Body

• Ii-Ore Bunkers

• Imizimba yePulverizer

• Udidi lwePulverizer

• Iicones

• Ukukhutshwa kwePulverizer

• Iivalvu

• Iintsimbi zeRock Bed Wall

• IiSilo kunye neeBunkers

• Iinguqu

• Ilori kunye neRail Car

• Iindawo zokulahla amalahle

• Iibhokisi zokuhlamba

• Izikrufu zaseWennberg