IiPaneli zokuGxila zeRabha ezishushu zeRabha yeCeramic Composite

I-Hot Vulcanization Rubber yeCeramic Composite Wear Panels Intshayelelo

Izisombululo ze-YIHO Wear Panel zifanelekile kwiindidi ezahlukeneyo zemigodi, ukusetyenzwa kweeminerali kunye nokuphathwa kwempahla yokukhusela ekugqokeni ngokugqithiseleyo.

A. Inkqubo yeCeramic kunye nerabha vulcanization ivuthiwe kwaye ithembekile.

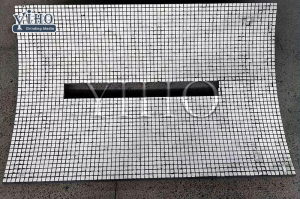

Kunyango lomphezulu we-ceramic phambi kokuba vulcanization, sisebenzisa i-agent yase-US yonyango lwangaphandle.Iimveliso ze-vulcanized Nokuba i-liner igobile i-360 °, i-ceramic ayiyi kuwa kwi-rubber.

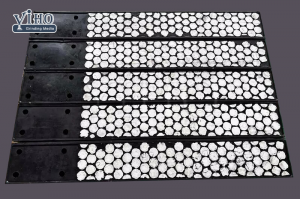

B. i-ceramic liner kunye nentsimbi yokunamathisela ngokuqinileyo

Kwi-ceramic liner kunye nentsimbi yokudibanisa, sisebenzisa isinyithi esingeniswe ngaphandle kunye ne-rubber adhesive.Imveliso inokubambelela okuqinileyo, ukumelana nobushushu obuhle, ukuxhathisa kwe-asidi kunye ne-alkali, ukuxhathisa ukubola, ukuchasana nokuguga njalo njalo.Njengoko irabha yerabha yerabha yenkampani incama incamathisela ekhethekileyo, phantse ishumi leminyaka ekusetyenzisweni kwamakhulu abathengi, ukuthembeka kuhle kakhulu, ukuza kuthi ga ngoku, akukho mveliso iphuma kule ngxaki.

Ubushushu bencamathelisa bezinto eziphilayo yi-100 ℃, elona qondo lisezantsi thabatha 50 ℃.Isebenza kakhulu kwirabha yerabha ehlanganisiweyo yelayini yokuncamathisela, ngenxa yokubambelela ngokuqinileyo kwe-viscose yendalo, ngelixa i-liner kunye nendawo yoqhagamshelwano yezixhobo inkulu, ifanelekile kakhulu kwimpembelelo enkulu, ukuguga okunzulu kunye nokukrazula kwenkqubo yokuhambisa izinto, ezifana nokuphatha amalahle eplanti yamandla. inkqubo, Steel, ukunyibilikisa sintering plant njalo njalo.

I-Hot Vulcanization Rubber yeCeramic Composite Wear yePaneli yesicelo

Imizekelo yosetyenziso oluqhelekileyo:

· IiChutes

· Izitshingitshane

· Abahlambi

· Imibhobho namatanki

· Amanqaku odluliselo lomthumeli

· Imiqadi yesikrini, iipaneli zangaphantsi kunye namalungu

· Izitya zokungcangcazela

I-Hot Vulcanization Rubber yeCeramic Composite Wear Panels Iimpawu eziphambili kunye neenzuzo

Iimpawu eziphambili kunye neenzuzo

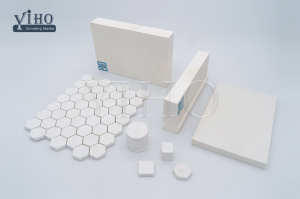

• I-92% ye-Aluminiyam oxide imathiriyeli.

• Ikhompawundi yerabha edityaniswe neepolima ze-CN.

• Umaleko odityanisiweyo we-CN kunye ne-buffed edges.

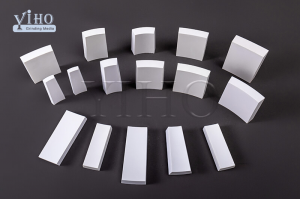

• Ubungakanani obulawulekayo kunye nobunzima.Ububanzi be-Strip 250mm benza kube lula ukuyifaka.

• Ukumelana nomlilo kunye ne-antistatic (FRAS) ikhompawundi yerabha ekhoyo.

• Irabha yesulfure ephantsi.

• Iithayile zeseram ezibotshelelwe kwirabha macala onke (ngaphandle komphezulu ongaphezulu).

• Inikwe kwiiphaneli ezisikwere 500mm x 500mm.

• Ukuxhathisa okugqithisileyo.

• Ukuncamathela okugqwesileyo kwiithayile zeceramic, irabha kunye nentsimbi.

• Ukuze uncamathelise i-vulcanised ebanda kakhulu.

• Ingasetyenziswa kwizicelo ezingaphezulu nangaphantsi komhlaba.

• Ukuqina kwerabha okuzinzileyo kunye nobudala.

• Uxhathise ukuqhekeka kwethayile kwaye uyitsale.

• Kulula ukuyifaka.

Irabha, iCeramic&Steel Specification

| S.No. | Izinto eziphathekayo | Iimpawu | Iipropati |

| 1 | Iithayile zeCeramic | Izinto eziphathekayo | 92%, 95%, T95%,99%, ZTA |

| 2 | Irabha | Icandelo | Irabha yendalo |

| Ukuxinana | 1.4g/cm3 | ||

| Amandla okuqina ngexesha lekhefu | ≥10.6Mpa | ||

| Ukwandisa ngexesha lekhefu | ≥350% | ||

| Ukuqina konxweme | 45-65 | ||

| I-Adhesive phakathi kwe-tile kunye ne-rubber | ≥3.8 Mpa | ||

| I-Adhesive phakathi kwerabha kunye nezixhobo | ≥3.58Mpa | ||

| I-Thermal conductivity.(ubushushu obuqhelekileyo) | 2w/m·k | ||

| Ixesha lokuguga | ≥15 Iminyaka | ||

| Ubushushu bokusebenza | -50ºC -200ºC | ||

| 3 | Ipleyiti yentsimbi | Izinto eziphathekayo | Q235A |

| Ukuxinana | 7.85g/cm3 | ||

| Ukutyeba | 3-10mm | ||

| 4 | Ukuncamathelisa | Imbonakalo | Ulwelo olumdaka olumdaka |

| Umxholo oqinileyo | 20±3% | ||

| Viscosity | ≥2.5 Mpa | ||

| Amandla e-Peel | 48h N/2.5cm≥120 | ||

| Amandla acinezelayo | ≥850 Mpa | ||

| Ubushushu bokusebenza | -20ºC -100ºC |