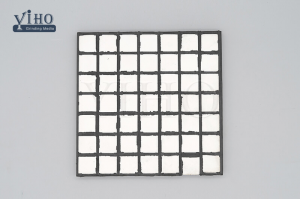

I-Hybrid Liner Rubber Ceramic Matrix

MALUNGA neHybrid Liner Rubber Ceramic Matrix

Ukudibanisa usebenzisa inkqubo ekhethekileyo, i-Hybrid Liner idibanisa izinto ezimbini ze-liner kunye neempawu zabo ezithandekayo.Ingaphakathi lenziwe nge-polyurethane kwaye ikhusela amalungu ashiyekileyo kunye nezakhiwo zamathambo ngenxa yeempawu zayo ezifunxa ukothuka.Kwangaxeshanye, iqinisekisa unikezelo loxinzelelo oluphezulu kuwo wonke amalungu ashiyekileyo, zombini ukwenza intshukumo kunye nesizukulwana esisebenzayo sevacuum.Umphandle we-liner kunye ne-vacuum flap edibeneyo yenziwe nge-silicone, ibonakaliswe ekusebenziseni imihla ngemihla ngenxa yokuqina kwayo.Oku kubaluleke ngakumbi xa i-vacuum flap isongelwe phezu kwesokethi yangaphakathi ukwenza isitywina esingangeni moya kwisistim.

Isicelo se-Hybrid Liner Rubber Ceramic Matrix

Kwimiba ye-abrasion ngokubhekiselele kwi-rubber linings, ezi nkcazo zilandelayo kufuneka ziqwalaselwe.

1- Zimbini iintlobo zokukrazuka umntu anokuthi adibane nazo, ukuzifaka kunye nokutyibilika.

I-2- Impingement abrasion yenzeke xa amasuntswana abetha umphezulu werabha (okanye nayiphi na enye indawo).

3- Ukutyibilika kwerabha kwenzeka xa omnye umphezulu utyibilika kwirabha.

4- Kuyo yonke imeko i-abrasion inokulindeleka ukuba ibe yindibaniselwano yokufakwa kunye nokutyibilika.

I-5- I-impingement abrasion iyenzeka ikakhulu kwi-chutes, kwi-sandblast hose naphi na apho kubonwa khona.

I-6- Kwinkqubo yokungena, iinqununu zibethe umphezulu kwaye naziphi na iingcinezelo eziveliswayo zisasazwa ngokulinganayo ukuba i-rubber ivelisa ngokulula, ngakumbi xa iinqununu zibetha kwi-angle ye-90 ° ukuya phezulu.

Izinto zeCeramics (iAlumina + iRection Bonded Silicon Carbide Tiles)

| Udidi | 92% Al2O3 | 95% Al2O3 |

| ZrO2 | / | / |

| Ukuxinana(gr/cm3) | >3.60 | >3.65g |

| HV 20 | ≥950 | ≥1000 |

| Ukuqina Kwamatye HRA | ≥82 | ≥85 |

| Ukugoba Amandla eMPa | ≥220 | ≥250 |

| Amandla oxinzelelo lweMPa | ≥1050 | ≥1300 |

| Ukuqina Kokwaphuka (Kic MPam 1/2) | ≥3.7 | ≥3.8 |

| Nxiba umthamo (cm3) | ≤0.25 | ≤0.20 |

| Isilicon CarbideIdatha(RBSiC) | ||

| Isalathiso | Ixabiso | Iziphumo zovavanyo |

| Sic | / | ≧90 |

| Ubushushu | ℃ | 1380 |

| Uxinaniso oluthile | g/cm3 | ≧3.02 |

| Vula i-Porosity | % | <0.1 |

| Imodyuli ye-elasticity: | I-Gpa | 330Gpa (20℃) 300Gpa(1200℃) |

| Ukuqina kukaMoh | / | 9.6 |

| Amandla okugoba | Mpa | 250(20℃)/ 280 (1200℃) |

| Amandla oxinzelelo | Mpa | 1150 |

| I-Coefficient yokwandiswa kwe-thermal: | / | 4.5K^(-3)*10^(-5) |

| I-Coefficient ye-thermal conductivity: | W/mk | 45 (1200℃) |

| I-Acid Alkaline -ubungqina | / | Egqwesileyo |