Iityhubhu zeCeramic kunye neengxenye ezikhethekileyo

Ulwakhiwo lweMveliso:

| Udidi | HC90 | HC92 | HC95 | HCT95 | HC99 | I-HC-ZTA | ZrO2 |

| Al2O3 | ≥90% | ≥92% | ≥95% | ≥ 95% | ≥ 99% | ≥75% | / |

| ZrO2 | / | / | / | / | / | ≥21% | ≥95% |

| Ukuxinana | >3.50g/cm3 | >3.60g/cm3 | >3.65g/cm3 | >3.70g/cm3 | >3.83g/cm3 | >4.10g/cm3 | >5.90g/cm3 |

| HV 20 | ≥900 | ≥950 | ≥1000 | ≥1100 | ≥1200 | ≥1350 | ≥1100 |

| Ukuqina Kwamatye HRA | ≥80 | ≥82 | ≥85 | ≥88 | ≥90 | ≥90 | ≥88 |

| Ukugoba Amandla eMPa | ≥180 | ≥220 | ≥250 | ≥300 | ≥330 | ≥400 | ≥800 |

| Amandla oxinzelelo lweMPa | ≥970 | ≥1050 | ≥1300 | ≥1600 | ≥1800 | ≥2000 | / |

| Ukuqhekeka kokuqina kwe-KIc MPam 1/2 | ≥3.5 | ≥3.7 | ≥3.8 | ≥4.0 | ≥4.2 | ≥4.5 | ≥7.0 |

| Nxiba iVolume | ≤0.28 cm3 | ≤0.25cm3 | ≤0.20cm3 | ≤0.15cm3 | ≤0.10 cm3 | ≤0.05cm3 | ≤0.02cm3 |

Imizekelo yokusebenzisa

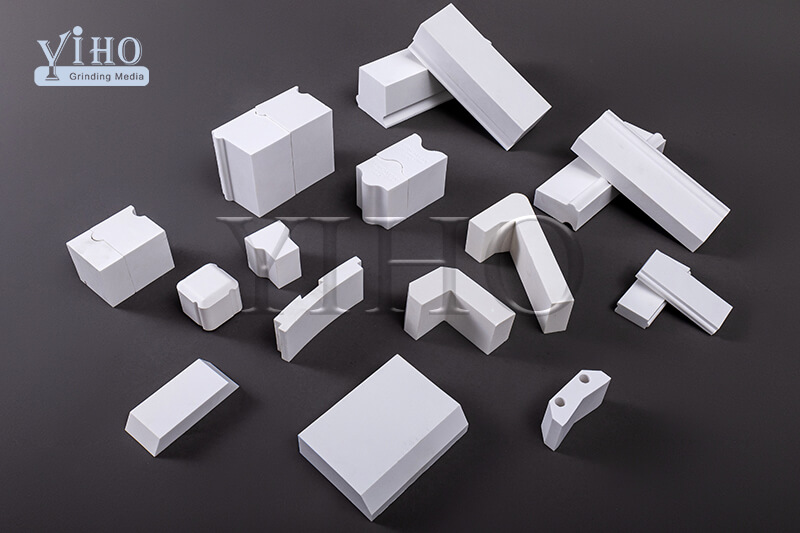

Amanqaku: Sinokwenza i-alumina inxibe i-tile ngokwemfuno yakho.

Iimbonakalo

Ukuqina okuphezulu

Ukuqina kwe-Rockwell yeeseramikhi eziphezulu ze-alumina ukuya kuthi ga kwi-HRA80-90 eyesibini kuphela kwidayimani kwaye ingaphezulu lee kwintsimbi ekwaziyo ukumelana nentsimbi.

Ukumelana nokunxiba okugqwesileyo

Ukumelana nokunxitywa kwe-alumina ceramics ephezulu ngamaxesha angama-266 ensimbi ye-manganese kunye namaxesha angama-171.5 okwentsimbi ye-chromium ephezulu. Ngokophando lwethu kunye nokulandelwa kubathengi, ubomi benkonzo yezixhobo bunokwandiswa ngaphezu kwamaxesha e-10 phantsi okufanayo. iimeko zokusebenza.

Ukumelana nokubola

Iiseramikhi zealumina eziphakamileyo zii-oksidi ze-inorganic kunye nesakhiwo semolekyuli ezinzile kakhulu kwaye akukho mhlwa we-electrochemical, ngaloo ndlela zinokuxhathisa ukhukuliseko lweasidi, ialkali, izisombululo zetyuwa kunye nezinyibilikisi eziphilayo.

UkuThermostability

Ubushushu bokusebenza be-alumina ceramics ephezulu bunokuba phezulu njenge-1400 ℃.

Ukuzithambisa okuhle

Iiseramikhi ze-alumina eziphakamileyo zineempawu zokuzithambisa kunye nokunamathela, uburhabaxa yi-1/6 kuphela yemibhobho yentsimbi ngaloo ndlela ukuhamba kancinci Ukumelana.

Ubunzima obulula

Ubuninzi beekeramics eziphezulu ze-alumina malunga ne-3.6g / cm3, esisiqingatha kuphela sentsimbi, ngoko kulula ukwakhiwa kunye nokufakwa.

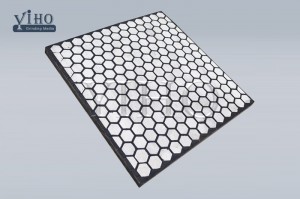

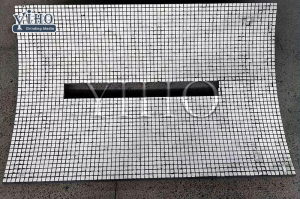

Nxiba izisombululo esibonelela ngazo

Le yinkqubo enzima.Iinjineli zethu ziqonda iingxaki zokunxiba kwaye zicacise

izisombululo ukuhlangabezana nemeko yakho yokusebenza.Iipropathi zezinto eziphathekayo, ukunyamezela, ukuthafa, iindlela zokuncamathela, kunye neendleko zezinto eziphathekayo zonke ziqwalaselwa kwimpahla yokunxiba.

Usetyenziso

• IiChutes/Hoppers

• IiKhowuni zoHlelo

• Izahluli zeNkanyamba

• Ingqiniba

• Izindlu zeefeni & iiBlades

• Imibhobho eneMibhobho

• Imilomo

• Nxiba iiPaneli

Iimarike

• Ukuveliswa koMbane okwenziwa ngamalahle

• UkuPhathwa kweMathiriyeli eAbrasive

• Ukwenziwa kweMichiza

• Ukwenziwa kokutya

• Ukwenziwa kwentsimbi/kweNsimbi

• UkuLungiswa kweeMbiwa

• Ukuhanjiswa kwePowder/Bulk Solids

• Ukwenziwa kwePulp & nePhepha

• Ukucoca nokuSila